This is my first successful bow of the year, 50# @28"

(an earlier Wych Elm primitive exploded after about a dozen shots! I shall be doing a "repair" and destruction test later, just to see how well linen binding supports a break).

The Yew was local to me, it had been felled by the council following some storm damage, and just left to rot.

The bow has some nice character is 66" from nock to nock, and the limbs are 2" wide at their widest.

Playlist for the entire build here:-

https://www.youtube.com/playlist?list=PLBz2tD9476KSe_bzPG5ZZRhW5_lEGsUWq

Friday 5 April 2024

English Yew Primitive

Saturday 13 January 2024

Dear Diary a log and repairs

I've been pressing on with the Hickory flight bow rework despite multiple failures, as it seems to be providing opportunity for experimentation and learning for relatively little expenditure of time and effort.

Meanwhile one of the guys from our 'club' (a bunch of blokes who lob arrows around a field between sampling flavoured rum and eating cakes) brought me a 5' length of Yew log and a bow which I'd made him a few years ago, but was now too heavy. He wanted the 70# boo, Yew, Lemonwood taken down to 50#).

I then got contacted via facebook about a bow repair, it turned out to be a Ravenbeak bow (Boo,Yew,Yew) that I'd repaired before to patch a belly chrysal. It looks like the chrysal has returned and presumably the patch needs to be thicker and more extensive (Maybe there is a weak area in the core ?)

Mean while I've decided to cut the yew log into 4' billets as the thin end was a bit scruffy. The log is still very fresh and green and my 3tip alternate set bandsaw blade was worn out. I started to sharpen it, but soon gave up and ordered two new blades (from Just Bandsaw Blades).

So while I'm waiting for the bandsaw blades I need to have a good tidy up. Th bloke will be bringing the Ravenbeak repair over on Wednesday, so that will be an excuse to have a go with the Chinese repeater etc.

Sunday 31 December 2023

Review of 2023

Been a funny year, it feels like I've not done much in the way of making bows, but I've still been busy.

The year started with a 120# Yew warbow from a fairly challenging stave, I did a 100# one too. I also tried for another 120, but the Austrian Yew was full of shakes and it split in two! I managed to repair it and turn it into a respectable 60# roving bow.

The mkii H Bow flight bow (pic left) performed fairly well, with some nice additions like the counterbalance/stabiliser weight, before exploding!

My mate Rob had given me some Rowan last year and I made a primitive with that, always nice to use a new timber. It preformed like most 'white woods' and felt like a cross between Ash and Hazel.

The scoop back Yew primitive was something a bit different and a delight to shoot.

The big project of the year was the mkii Archer Automaton which was hard work, educational, frustrating and great fun in equal measure.

I'm currently reworking a shoot through Hickory Flight bow, which like all my stuff is now mostly on my youtube channel.(Del Cat@delcat8168)

This blog has reverted to its original purpose which is as an aide memoire for me, this post providing a useful summary of the year.

My last little project of the year was making some little box wood clamps (with M6 threaded rod for the screws) to assist the glue up of the Hickory flight bow levers. (2shown, but I made 3)

Of course it's also an opportunity to wish one and all a happy new year. May all your projects bear fruition, or at least provide some enjoyment and may all your arrows find their mark.

Del

Wednesday 27 December 2023

Old Flight Bow Progress

Seasons greetings to one and all. I've been doing some post Christmas tinkering in the garage/workshop.

I've taken off about 4mm of chrysalled belly wood and glued on slats of heat treated Yew heart wood. I've used a slat of Yew (~5mm thick) to construct the levers, making them a T section.

It's been up on the tiller for a quick shufti and I can see the levers are flexing.(mostly at the inner end) They are bound to flex a bit but I was expecting them to be stiffer. I can experiment by gluing on an additional strip to make them I section, which should help.

I used hide glue which can be released with gentle heat, so if necessary I can rebuild the levers a tad thicker and deeper maybe even V section.

Wednesday 6 December 2023

Reworking a Flight Bow

I've got an old Hickory shoot-through flight bow with a chrysalled belly. It was a bit lethal, as I was trying to shoot it, finger loosing it, this set the arrows flexing and they tended to smash. Since then I've made a release aid, and that is probably the key to getting the shoot-through to work.

I'm going to rasp/machine off the belly (the chrysals go about 4mm deep) and add a new belly of heat treated Yew heart wood.

I'm aiming for 50# at 24" draw with a very light arrow.

Most of my stuff is on my Youtube channel now, but this post is really a log of what I'm aiming for with this bow.The bow is a Mollegabet style and I think the levers are a bit long and heavy, so they may get reduced during test/development.One dilemma is how do I terminate the new belly at each end where the thickness of the original bow increases at the grip and the levers? I'm favouring a simple butt joint, which, being in compression should hold. I'm concerned that if I try and fade it out at each end it may lift or splinter.

Tuesday 17 October 2023

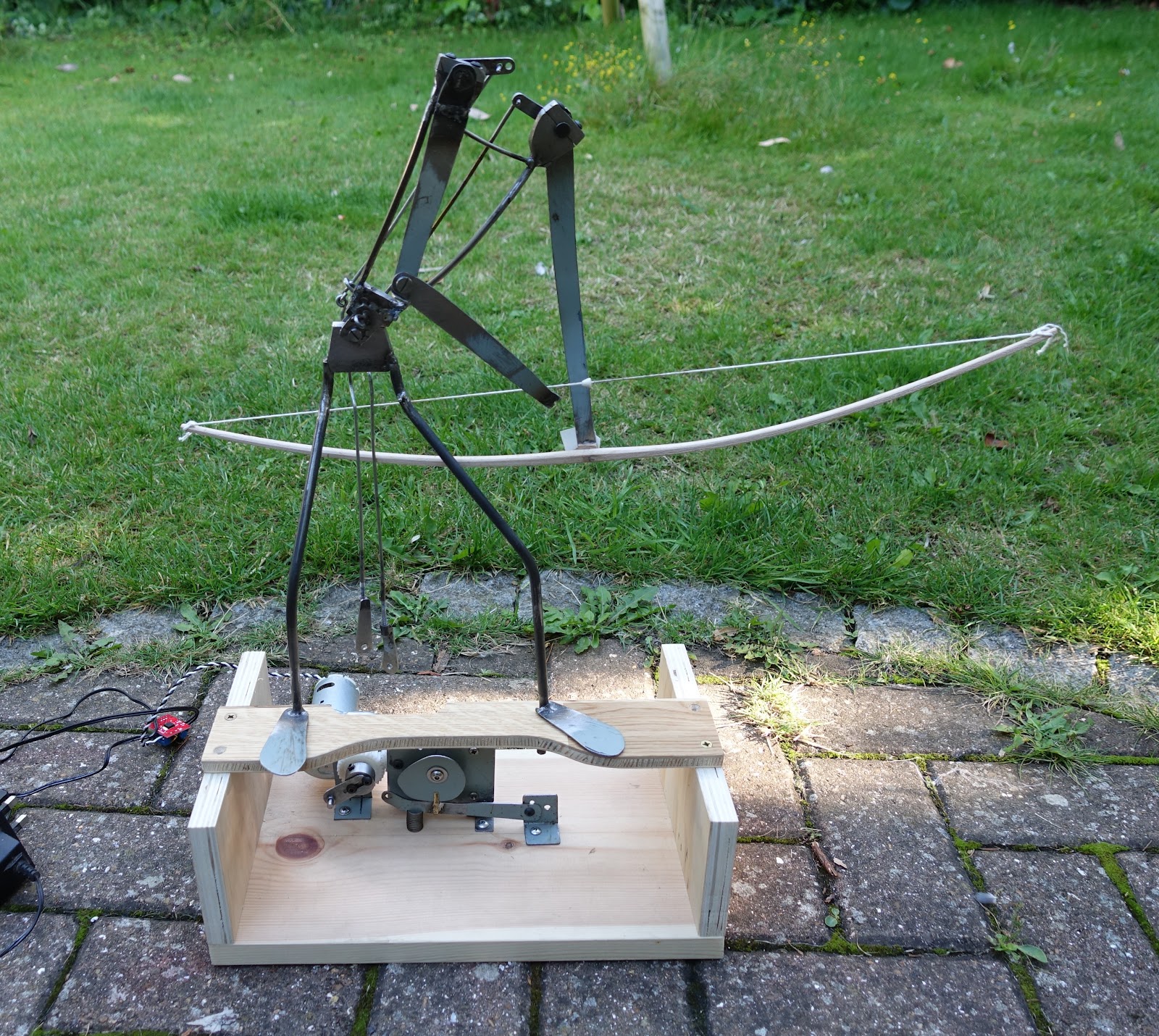

Mkii Archer Automaton

I've got it working pretty reliably now. Still lots of cosmetic stuff to do.

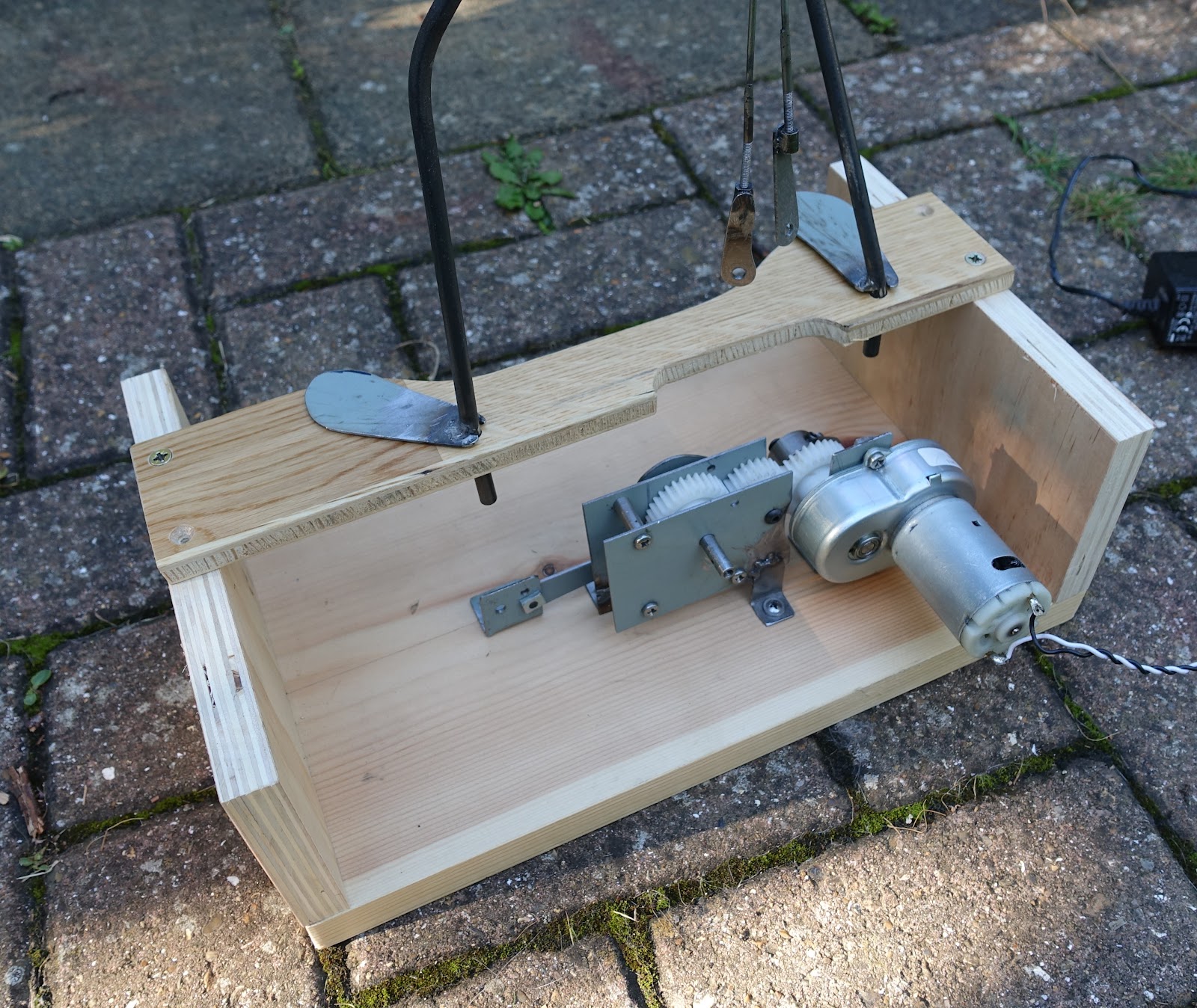

The basic movement is done by 2 control rods, one on a crank and the other (bow arm) on a cam. I've gone through about 9 iterations of the cam, and I've just made a new one, to try and get the two arms coming up together. It works very well and is a big improvement.

In the video you can see the bow arm comes up a bit too early ( or a medieval style draw).

There has been an immense amount of fiddling and fettling, but it all slowly improves the reliability and repeatability.

It's motorised now so that pressing a button starts it, and then it stops after the arrow is loosed, as the microswitch is actuated (see bottom pic)

https://www.youtube.com/watch?v=eDJvVBdDx54

Thursday 10 August 2023

Work on the mkii Archer Automaton

This has been a long term ongoing project that entails endless thought, lots of trial and error and a huge amount of patience.

I makes me realize that a bit like making a bow, it's not all about the end result. The pleasure is in the art and craft, the problem solving and actually doing something with ones hands. Enjoying the process makes the required patience a joy rather than a chore.

Almost every part of the automaton has been made multiple times, and there are unexpected interactions between the moving parts. The linkages, pivot points, and movements all interact, and the timing between the various motions need to be precise.

I've built it up slowly, getting one aspect to work and then progressing to the next. Of course once the next action works nicely, the first one may no longer function! But by then the understanding of the motion has been enhanced.

Originally the motor/gearbox mas mounted between the feet, but I've built a plinth such that the motor/gearbox will now be below 'ground level'.

The biggest challenge has been to get him to collect the arrow on the string. The next big challenge is the loosing mechanism.

Over the development I've had to try 3 different motor/gearboxes, unfortunately the best one stripped an internal tooth. I found some great ones on E-bay, with the requisite very low gearing and hopefully enough output torque to draw the bow. (I'm waiting for it to be delivered).

Originally the 2 main movements were on cranks, one of these has been changed to a cam as it can be adjusted to give an asymmetric motion. I'll probably retain the right arm motion as a simple crank otherwise I'll end up with too many variables to adjust.